Introduction: In the realm of logistics and supply chain management, the choice of pallets plays a critical role in ensuring the safe and efficient transportation of goods. Among the various options available, heat treated pallets have gained significant popularity due to their numerous advantages. At Custom Forest Products, we recognize the importance of these pallets and the positive impact they can have on your operations. In this blog post, we will explore the distinct benefits of heat treated pallets and why they are an excellent choice for streamlined logistics.

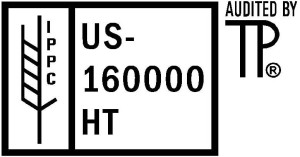

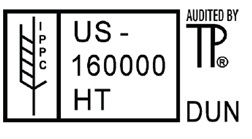

- Compliance with International Phytosanitary Standards: Heat treated pallets undergo a specialized heat treatment process known as heat treatment (HT). This treatment ensures that pests, insects, and pathogens are effectively eradicated from the wood, making the pallets compliant with international phytosanitary standards, such as ISPM 15. This compliance is particularly crucial for companies engaged in international trade, as it helps prevent the spread of harmful organisms and ensures seamless customs clearance.

- Enhanced Durability and Structural Integrity: Heat treated pallets are subjected to high temperatures that remove excess moisture from the wood. This process significantly reduces the risk of decay, rot, and mold growth, which can compromise the structural integrity of the pallets. By choosing heat treated pallets from Custom Forest Products, you can rely on their enhanced durability, prolonging their lifespan and reducing the need for frequent replacements. This durability translates into cost savings and increased operational efficiency.

- Reduced Risk of Contamination: With traditional pallets, there is a potential risk of chemical contamination due to the use of certain treatments and coatings. Heat treated pallets eliminate this concern, as they rely solely on heat to ensure the wood’s integrity. By using heat treated pallets from a trusted provider like Custom Forest Products, you can have peace of mind knowing that your goods are transported on pallets that pose minimal risk of chemical contamination.

- Universal Compatibility and Increased Efficiency: Heat treated pallets are universally recognized and accepted for international shipping. They can seamlessly integrate with automated systems, conveyor belts, forklifts, and other machinery commonly used in warehouses and distribution centers. Their standardized dimensions and consistent quality make them highly compatible and enable smooth operations throughout the supply chain. By utilizing heat treated pallets, you can enhance productivity, reduce handling time, and minimize disruptions in your logistics processes.

- Environmental Responsibility and Sustainability: Heat treated pallets align with sustainable practices, making them an environmentally responsible choice. The heat treatment process does not involve the use of chemicals or harmful substances, reducing the carbon footprint associated with traditional pallet treatments. Additionally, heat treated pallets can be recycled or repurposed, contributing to the circular economy and reducing waste.

Conclusion: Heat treated pallets offer significant advantages that streamline logistics operations and enhance overall efficiency. With compliance to international phytosanitary standards, improved durability, reduced risk of contamination, universal compatibility, and sustainability benefits, these pallets are a reliable choice for businesses seeking optimized supply chain management. At Custom Forest Products, we provide high-quality heat treated pallets that meet stringent industry standards and cater to your specific needs. Make the smart choice and partner with us to experience the benefits of heat treated pallets in your logistics operations.